Welcome to our Company

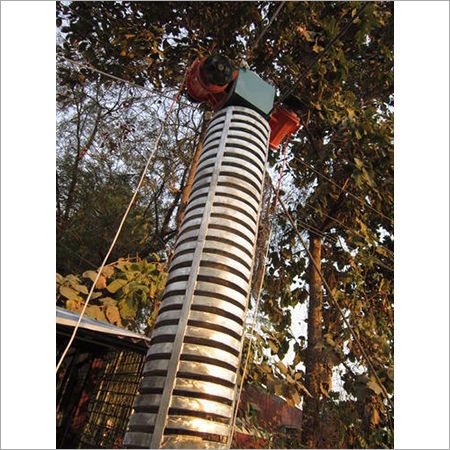

Unbalance Motorized Spiral Elevator

200000.00 - 800000.00 INR/Unit

Product Details:

- Features Can Handle Hot or Cold Products, Stainless Steel Construction Option

- Equipment Type Material Lifting Equipment

- Belt Type No Belt Helical Shaft Drive

- Rotation Type Clockwise/Counter-Clockwise (Customizable)

- Control System PLC Based Control Panel

- Lifting Speed Variable, up to 20 m/min

- Motor Type Unbalance Motor (Vibratory)

- Click to View more

X

Unbalance Motorized Spiral Elevator Price And Quantity

- 1 , , Unit

- 200000.00 - 800000.00 INR/Unit

- Less than 75 dB

- Customizable, Up to 6 meters

- Mild Steel / Stainless Steel (As Per Requirement)

- Conveying Granules, Powder, Food Products, Chemicals

- 300800 mm (Model Dependent)

- Vertical, Floor Mounted

- Powder Coated / Polished

- Emergency Stop, Overload Protection

- Single or Double as per design

- -10C to +50C

Unbalance Motorized Spiral Elevator Product Specifications

- 500 kg/hour

- 220-415V AC

- Gentle Product Handling, Energy Efficient

- Up to 500 kg/hr

- Electric

- Unbalance Motor (Vibratory)

- Not Applicable (Spiral Tube Design)

- New

- Variable, up to 20 m/min

- PLC Based Control Panel

- No Belt Helical Shaft Drive

- Clockwise/Counter-Clockwise (Customizable)

- 6 meters

- Can Handle Hot or Cold Products, Stainless Steel Construction Option

- Material Lifting Equipment

- Continuous Vertical Lifting, Low Vibration, Low Noise

- 27.5 kW (Depending on Model)

- Less than 75 dB

- Customizable, Up to 6 meters

- Mild Steel / Stainless Steel (As Per Requirement)

- Conveying Granules, Powder, Food Products, Chemicals

- 300800 mm (Model Dependent)

- Vertical, Floor Mounted

- Powder Coated / Polished

- Emergency Stop, Overload Protection

- Single or Double as per design

- -10C to +50C

Unbalance Motorized Spiral Elevator Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Dadra and Nagar Haveli, Chandigarh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, , Lakshadweep, Chhattisgarh, Nagaland, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Delhi, Gujarat, Kerala, Central India, Odisha, West India, Himachal Pradesh, Uttar Pradesh, All India

Product Description

Unbalance Motorized Spiral Elevator

Unbalance Motorized Spiral Elevator is an industrial grade materials conveying unit which is widely used for the continuous elevating of the solid materials in vertical directions. This heavy unit is equipped with a high performance motor which transfers the rotational power to this machinery. It is enclosed in a metal casing which helps to protect it from the dust and dirt. It requires very low maintenance and consumes less electricity which results low operational cost.

Advanced Vertical Material Lifting Solution

Engineered for versatility, the unbalance motorized spiral elevator delivers reliable and continuous vertical movement for materials in food, chemical, and industrial applications. Its spiral tube design, powered by a vibratory unbalance motor, ensures gentle product handling and consistent throughput with minimal noise and energy consumption. The equipment is tailored to specific requirements, offering a choice between single or double starts, varied material options, and customizable control features for seamless integration.

Superior Safety and Efficiency Features

Operator comfort and workspace safety are prioritized through built-in emergency stop and overload protection, keeping the maximum noise level below 75 dB. The low vibration design ensures long service life. With energy efficiency at its core, the spiral elevator requires minimal maintenance due to its beltless helical shaft drive and solid construction, making it a practical investment for modern production environments.

FAQs of Unbalance Motorized Spiral Elevator:

Q: How does the unbalance motorized spiral elevator operate?

A: This elevator utilizes an unbalance motor to create vibrations, powering a helical shaft that elevates materials vertically. There is no conventional belt; instead, items move up the spiral tube through vibration and the spirals geometry. The lifting speed can be adjusted up to 20 meters per minute using the PLC-based control panel.Q: What materials and products can this spiral elevator handle?

A: It is designed to convey a wide range of materials, including granules, powders, food products, and chemicals. The elevators construction in mild steel or stainless steel allows it to handle both hot and cold products efficiently, making it suitable for diverse industries such as food processing, pharmaceuticals, and chemicals.Q: When should I consider using a spiral elevator for my application?

A: You should use a spiral elevator when you require continuous, gentle, and efficient vertical transport of bulk materials, especially in environments where floor space is limited or when low noise and vibration are critical. This equipment is ideal for up to 500 kg/hour and a maximum height of 6 meters.Q: Where is the unbalance motorized spiral elevator typically installed?

A: This equipment is floor-mounted and commonly installed in production facilities, warehouses, or processing plants where vertical lifting of materials is needed. Its compact, vertical design allows it to be situated even in areas with space constraints.Q: What advantages does the spiral elevator offer over conventional conveying systems?

A: Compared to traditional belt or bucket conveyors, this spiral elevator provides gentler handling, requires less maintenance due to its beltless design, operates more quietly (below 75 dB), and is energy efficient. Its customizability and robust safety features further enhance operational reliability.Q: How can the elevator benefit my production process?

A: By enabling the continuous, vertical movement of materials with minimal downtime, low noise, and low vibration, the spiral elevator improves productivity and maintains product integrity. The customizable configurations and PLC-based controls facilitate integration into automated processes, delivering reliable and efficient material handling.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese