Welcome to our Company

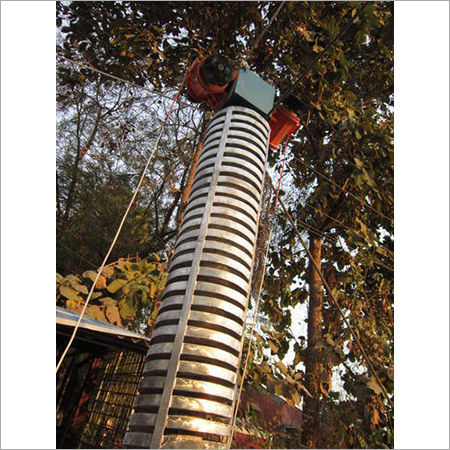

Motorized Spiral Elevator

350000.00 - 1000000.00 INR/Unit

Product Details:

- Control System PLC Controlled

- Motor Type Three Phase Induction Motor

- Lifting Speed 0.5 2 m/sec

- Wheel Type Stationary Base, No Wheels

- Belt Type Modular Plastic Belt

- Equipment Type Material Handling Elevator

- Features Customizable Design

- Click to View more

X

Motorized Spiral Elevator Price And Quantity

- 01 Unit

- 350000.00 - 1000000.00 INR/Unit

- Motorized Gear Drive

- < 65 dB

- Powder Coated/Polished

- -10°C to +45°C

- Cartons, Trays, Bottles, Bulk Goods

- Minimal, Easy Access Panels

- Emergency Stop, Overload Protection, Safety Guards

- Mild Steel / Stainless Steel

- Indoor/Outdoor

Motorized Spiral Elevator Product Specifications

- Continuous Vertical Transport

- PLC Controlled

- Customizable, typically up to 50 meters

- Up to 10 meters

- Up to 1000 kg

- 0.5 2 m/sec

- Automatic Operation, High Throughput

- Three Phase Induction Motor

- 3 7 kW

- 380V / 3 Phase

- 1000 kg

- Stationary Base, No Wheels

- Modular Plastic Belt

- Electric

- Customizable Design

- Material Handling Elevator

- New

- Spiral (Helical)

- Motorized Gear Drive

- < 65 dB

- Powder Coated/Polished

- -10°C to +45°C

- Cartons, Trays, Bottles, Bulk Goods

- Minimal, Easy Access Panels

- Emergency Stop, Overload Protection, Safety Guards

- Mild Steel / Stainless Steel

- Indoor/Outdoor

Motorized Spiral Elevator Trade Information

- Vadodara , Gujarat

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Per Week

- 1-2 Week

- Yes

- Contact us for information regarding our sample policy

- Standard

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Tripura, Manipur, Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, All India, Daman and Diu, Lakshadweep, West Bengal, East India, Jammu and Kashmir, Meghalaya, Maharashtra, Jharkhand, South India, Assam, Mizoram, Bihar, Goa, Arunachal Pradesh, , Punjab, Sikkim, Rajasthan, Haryana, Delhi, Gujarat, Tamil Nadu, Madhya Pradesh, Karnataka, North India, Telangana, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, Uttar Pradesh

Product Description

We are manufacturer and supplier a qualitative range of Unbalance Motorized Spiral Elevator to our huge clientele base. It is made under the vigilant eye of our professionals, using tested quality raw material and advanced technology and machinery at our unit. Unbalance Motorized Spiral Elevator stand high on performance, efficiency, durability, and has a long service life. Clients can avail it from us at highly pocket-friendly prices in the market. In addition, we try to make delivery of the spiral elevator within fixed time-limit.

Features:

- Strong construction

- Outstanding performance

- Longer working life

- Requires less maintenance

Versatile Material Handling Solution

Engineered as a continuous vertical conveyor, the Motorized Spiral Elevator streamlines the transfer of various productscartons, trays, bottles, and bulk items. Its modular design supports customization of lifting height, belt length, and overall configuration to fit specific industrial requirements, making it highly adaptable for manufacturing, warehousing, or distribution settings.

Safety and Efficiency Combined

Safety is at the forefront of this elevators design, featuring emergency stops, overload protection, and comprehensive safety guards. Its PLC-controlled system ensures precise and safe operation, even at high throughput levels. The conveyor remains quiet during operation, emitting less than 65 dB of noise, supporting a safer, more comfortable work environment.

Durable Construction and Easy Maintenance

Constructed from mild steel or stainless steel with powder-coated or polished finishes, the elevator is designed to last in demanding settings. Maintenance is streamlined with minimal upkeep requirements and easy-access panels, minimizing downtime and maintaining high operational productivity.

FAQs of Motorized Spiral Elevator:

Q: How does the Motorized Spiral Elevator transport products vertically?

A: The elevator uses a motorized gear drive with a modular plastic belt arranged in a spiral (helical) configuration to continuously move products such as cartons, trays, bottles, and bulk goods vertically between floors or platforms.Q: What safety mechanisms are incorporated in this spiral elevator?

A: It includes emergency stop buttons, overload protection, and comprehensive safety guards to ensure a secure environment for both operators and products. The system is also PLC-controlled for added operational safety and precision.Q: When is it recommended to use this spiral elevator?

A: This equipment is ideal when you require efficient and continuous vertical transport of materials in indoor or outdoor industrial environments, particularly where high throughput, minimal maintenance, and customizable configuration are priorities.Q: Where can this material handling elevator be installed?

A: The Motorized Spiral Elevator is suitable for both indoor and outdoor locations, thanks to its rugged frame material options and weather-resistant finishing, making it adaptable for manufacturing plants, warehouses, or distribution centers.Q: What is the maintenance process for this elevator?

A: Maintenance requirements are minimal due to the durable structure and easy-access panels. Regular checks mainly involve motor and belt inspection, with most upkeep possible without specialized tools or extended downtime.Q: How does the customizable design benefit operations?

A: Customizable features such as belt length (up to 50 meters) and lifting height (up to 10 meters) allow the elevator to be tailored for specific site and application requirements, maximizing efficiency and space utilization.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese