Welcome to our Company

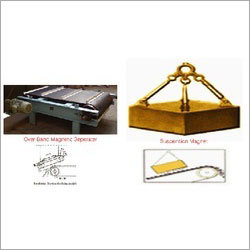

Over Band Magnetic Separator

Product Details:

- Voltage 220-415 V AC

- Magnet Grade Ferrite / Rare Earth

- Application Separation of ferrous contaminants from conveyed materials

- Material Mild Steel / Stainless Steel (custom)

- Power 2-6 kW (Depending on model)

- Surface Finish Powder Coated / Painted

- Frequency 50-60 Hz

- Click to View more

X

Over Band Magnetic Separator Price And Quantity

- 1 Piece

- -10°C to 80°C

- Cross Belt / Inline Over Conveyor

- Rubber with cleats (heat & wear resistant)

- Included / Optional

- 100 mm to 350 mm

- Up to 4.5 m/s

- Self-cleaning via rotating belt

- IP54/IP65 (as per requirement)

- Designed for continuous operation

Over Band Magnetic Separator Product Specifications

- Magnetic Separator

- Customized (as per conveyor width), typically 400 mm to 2000 mm

- Separation of ferrous contaminants from conveyed materials

- Ferrite / Rare Earth

- Mild Steel / Stainless Steel (custom)

- Overband Magnet

- 1 TPH to 30 TPH

- 220-415 V AC

- Permanent / Electromagnetic

- Magnet, Mild Steel Structure

- Blue / Yellow / Custom

- Electric

- Rectangular

- 300-1500 kg (model dependent)

- 2-6 kW (Depending on model)

- Recycling, Mining, Quarry, Cement, Coal, Food Processing, Aggregate, etc.

- 50-60 Hz

- Powder Coated / Painted

- -10°C to 80°C

- Cross Belt / Inline Over Conveyor

- Rubber with cleats (heat & wear resistant)

- Included / Optional

- 100 mm to 350 mm

- Up to 4.5 m/s

- Self-cleaning via rotating belt

- IP54/IP65 (as per requirement)

- Designed for continuous operation

Over Band Magnetic Separator Trade Information

- Per Week

- 1-2 Week

- Yes

- Contact us for information regarding our sample policy

- High Quality Packaging

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

Product Description

Our Over Band Magnetic Separator is designed for installation over conveyors where tramp iron impurity exists. It is widely used for removing magnetic parts from non magnetic materials in order to protect crusher, mills, processing plants and many more options. This magnetic separator is used for cleaning non magnetic goods with iron contamination, cleaning of foundry sand and the like. Moreover, Over Band Magnetic Separator is used for recovering magnetic material from steel mill, ore etc.

Working Principle:

The separator consist of rolled and driven motor at the center stationary magnet and then belt is passing through the magnet. In between this oration if any trump iron is found on the surface of conveyor, it will be attracted towards the magnet and then discharge once intersub of magnet field is over. Our tube of design is suggested when there will be huge amount ferrous material is detected.

Features:

Application:

Additional Information:

Minimum Order Quantity: 1 Piece

Working Principle:

The separator consist of rolled and driven motor at the center stationary magnet and then belt is passing through the magnet. In between this oration if any trump iron is found on the surface of conveyor, it will be attracted towards the magnet and then discharge once intersub of magnet field is over. Our tube of design is suggested when there will be huge amount ferrous material is detected.

Features:

- Very safe in flame proof area.

- Very much recommended in dusty humid and hostile condition.

- No power supply is required for magnet hence no maintenance.

- Very idea when no man power is available being a self cleaning design.

Application:

- Separate ferrous material from coal handling plant.

- Useful in collect ferrous material form slag.

- Separate chills, swaggers from foundry .

- Recommend to use in waste recycle to collect ferrous material.

- It is useful the use before pulverizes,screw conveyor, roto feeder etc.

Additional Information:

Minimum Order Quantity: 1 Piece

Self-Cleaning Efficiency for Continuous Operation

Equipped with a rotating belt mechanism, the Over Band Magnetic Separator delivers uninterrupted self-cleaning, ensuring that ferrous contaminants are swiftly removed from conveyed materials. This design minimizes manual intervention and sustains high productivity, even in the most demanding environments.

Versatile & Robust Engineering

Built from mild or stainless steel with a powder-coated or painted finish, the separator is engineered to handle challenging industrial environments. Its mounting flexibility (cross belt or inline) and suspension height adjustability (100 mm to 350 mm) make it adaptable to various conveyor setups and material flows.

Customizable to Fit Your Application

With size ranges from 400 mm to 2000 mm and capacities from 1 TPH to 30 TPH, this separator is customized to match conveyor widths and throughput requirements. Options in magnet grade (Ferrite or Rare Earth), type (Permanent/Electromagnetic), and control panel configurations ensure compatibility and optimized separation efficiency.

FAQs of Over Band Magnetic Separator:

Q: How does the self-cleaning mechanism function in this Over Band Magnetic Separator?

A: The Over Band Magnetic Separator uses a rotating belt with cleats that automatically remove ferrous contaminants from conveyed materials and discharge them outside the magnetic field, minimizing manual cleaning and supporting continuous operation.Q: What types of mounting configurations are available for this separator?

A: This separator can be mounted either as a cross belt above the conveyor or inline over the conveyor, allowing flexible integration into various material handling setups and optimizing separation efficiency.Q: When should I choose a permanent magnet versus an electromagnetic model?

A: A permanent magnet is recommended for applications with consistent ferrous contamination levels and lower maintenance needs, while the electromagnetic option suits environments requiring adjustable magnetic strength for variable contamination loads.Q: Where can this separator be used effectively?

A: The equipment is ideal for industries such as recycling, mining, quarrying, cement, coal, food processing, and aggregate handling, where reliable extraction of ferrous contaminants is essential for material purity and equipment protection.Q: What is the process for sizing and customizing the separator to my conveyor?

A: You provide your conveyor width and desired capacity, and the separator is tailored accordingly, with models available in widths from 400 mm to 2000 mm and capacities up to 30 TPH. Optional features such as control panels and surface finishes can also be specified during customization.Q: Can the separator operate continuously, and what is its service life?

A: Yes, it is engineered for continuous, round-the-clock operation with robust construction and wear-resistant belt materials, ensuring a long service life even under demanding industrial conditions.Q: What are the primary benefits of using an Over Band Magnetic Separator with a rubber cleated belt?

A: Key benefits include efficient ferrous contamination removal, minimal maintenance due to self-cleaning, adaptability to different conveyor setups, enhanced equipment protection, and improved material quality for downstream processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese