Welcome to our Company

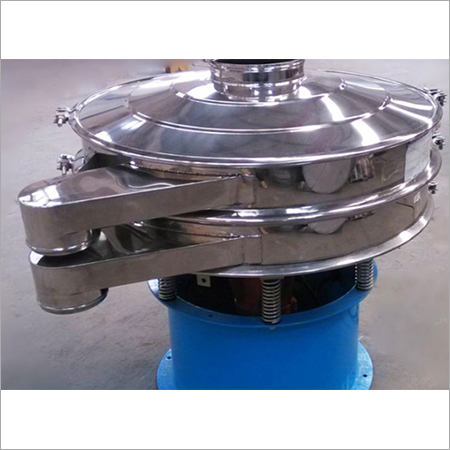

Circular Vibratory Screen

50000.00 - 300000.00 INR/Unit

Product Details:

- Type Circular Vibratory Screen

- Material Stainless Steel

- Capacity Up to 5 TPH (varies by mesh size)

- Computerized No

- Automatic Grade Semi-Automatic

- Voltage 220 - 415 V

- Frequency (MHz) 50/60 Hz

- Click to View more

X

Circular Vibratory Screen Price And Quantity

- 50000.00 - 300000.00 INR/Unit

- 1 Unit

- Eccentric Type/Direct Drive

- 0.52 HP (depending on size and model)

- Side or Bottom Discharge

- SS304/SS316

- Polished/Matte

- Low

- Up to 98%

- Single/Double/Multiple available

- Up to 10 mm

- Screening, Grading, Sifting of powders and granules

Circular Vibratory Screen Product Specifications

- 600 mm 1500 mm (Diameter options)

- 50/60 Hz

- 220 - 415 V

- Stainless Steel

- Up to 5 TPH (varies by mesh size)

- Varies with model

- Semi-Automatic

- Depends on model and configuration

- Circular Vibratory Screen

- As per design specification

- No

- Eccentric Type/Direct Drive

- 0.52 HP (depending on size and model)

- Side or Bottom Discharge

- SS304/SS316

- Polished/Matte

- Low

- Up to 98%

- Single/Double/Multiple available

- Up to 10 mm

- Screening, Grading, Sifting of powders and granules

Circular Vibratory Screen Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Western Europe, Australia, Middle East, South America, Asia, Central America, Eastern Europe, North America, Africa

- Tripura, Manipur, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, , South India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Haryana, Delhi, Gujarat, Madhya Pradesh, North India, East India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, Uttar Pradesh, All India

Product Description

Circular Vibratory Screen

The offered Circular Vibratory Screen is especially designed for the industries such as food, pharmaceutical, beverage, nutraceutical and agriculture for the removal of the impurities and to separate the particles as per their size. It is equipped with a series of meshing screens of different grades which allows to pass different sized particles due to the vibrating forces. The materials used for the fabrication of frame is stainless steel which offers resistance against vibrations and corrosion.

Versatile Screening Solutions

Designed to meet diverse industrial requirements, the Circular Vibratory Screen provides reliable performance for screening, grading, and sifting tasks. Choose from single, double, or multiple decks according to process needs, and select from side or bottom discharge depending on your material flow requirements. Its stainless steel build ensures durability and hygiene, making it suitable for industries like food, pharmaceuticals, minerals, and chemicals.

Efficient Performance and Customization

Experience high efficiency with up to 98% screening accuracy in powder and granule processing. The machines wide range of mesh sizes and motor power options (0.52 HP) cater to different processing capacities up to 5 TPH. Customize diameter, deck numbers, and discharge outlets for maximum operational flexibility. Its low noise level and polished surface finish further enhance user experience and workplace safety.

FAQs of Circular Vibratory Screen:

Q: How is the Circular Vibratory Screen installed and operated in industrial settings?

A: Installation is straightforwardplace the unit on a stable surface and connect it to a power supply within 220415 V. Feed material (up to 10 mm size) is input at the top, and the semi-automatic system uses eccentric or direct drive to vibrate the screens, facilitating efficient screening and discharge through side or bottom outlets.Q: What materials are compatible with the Circular Vibratory Screen, and how does the screen mesh selection affect the process?

A: This screen is optimized for powders and granules, with SS304 and SS316 mesh materials offering corrosion resistance and sanitation. Mesh size selection directly influences particle size separation and throughput capacity, allowing for tailored screening, grading, or sifting operations.Q: Where can this equipment be used and in which industries is it most beneficial?

A: The Circular Vibratory Screen is ideally used in industries such as food processing, pharmaceuticals, chemicals, minerals, and agriculture. Its robust and hygienic stainless steel design meets sector-specific standards for safe and efficient bulk material handling.Q: What is the process for cleaning and maintaining the vibratory screen?

A: Regular maintenance involves shutting down the unit, removing the mesh for cleaning, and inspecting drive components. A polished surface finish facilitates easy cleaning, while low-noise operation reduces wear. Routine checks for mesh integrity and motor functionality help maintain optimal performance.Q: What benefits does the multi-deck configuration offer over single-deck models?

A: Multi-deck configurations enable simultaneous screening into multiple fractions, improving efficiency and throughput. This setup is ideal for complex grading requirements or high-volume operations demanding precise product separation.Q: How is the capacity of up to 5 TPH achieved and what factors influence it?

A: Capacity depends on mesh size, feeding rate, material type, and selected motor power. The machines customizable diameter (6001500 mm) and robust drive options ensure consistent performance, while mesh design and discharge type enable efficient processing of different materials.Q: When is it recommended to choose an eccentric type drive over direct drive for the vibratory screen?

A: Eccentric type drives are favored for applications requiring powerful and adjustable vibration, handling heavier loads or larger capacities. Direct drive is suitable for consistent, moderate-duty screening tasks. Selection depends on material characteristics, deck number, and desired screening intensity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese