Welcome to our Company

High Intensity Magnetic Roller System

500000.00 INR/Unit

Product Details:

- Magnet Grade NdFeB/N52

- Frequency 50-60 Hz

- Power 2-5 kW

- Application Separation of ferrous contaminants from dry materials

- Voltage 220-380 V

- Composite Yes

- Material Stainless Steel body, High-Intensity Rare Earth Magnets

- Click to View more

X

High Intensity Magnetic Roller System Price And Quantity

- 500000.00 INR/Unit

- 01 Unit

- Belt Conveyor with adjustable speed

- Digital/Manual with safety features

- Up to 80°C

- Dustproof and vibration-free

- 150 mm to 400 mm

- Semi-Automatic/Automatic

- Up to 5 mm

- Single/Double/Triple (as per requirement)

- Floor Mounted

High Intensity Magnetic Roller System Product Specifications

- 100 kg/hr to 10 Ton/hr

- Yes

- 220-380 V

- Separation of ferrous contaminants from dry materials

- Electric

- Stainless Steel body, High-Intensity Rare Earth Magnets

- Polished/Matte

- Varies as per model (approx. 250-700 kg)

- Roller/Cylindrical

- NdFeB/N52

- Rare Earth Magnet

- Customized (varies from 300 mm to 2000 mm width)

- 50-60 Hz

- High Intensity

- Blue & Silver/Grey

- Used in mining, ceramics, chemical, food and plastics industries for fine ferrous separation

- Magnetic Roller Separator System

- 2-5 kW

- Belt Conveyor with adjustable speed

- Digital/Manual with safety features

- Up to 80°C

- Dustproof and vibration-free

- 150 mm to 400 mm

- Semi-Automatic/Automatic

- Up to 5 mm

- Single/Double/Triple (as per requirement)

- Floor Mounted

High Intensity Magnetic Roller System Trade Information

- Vadodara , Gujarat

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Per Week

- 1-2 Week

- Yes

- Contact us for information regarding our sample policy

- Standard

- Asia, Australia, North America, Eastern Europe, Western Europe, Central America, Middle East, South America, Africa

- Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, , Punjab, Karnataka, Tamil Nadu, Rajasthan, Pondicherry, Goa, Tripura, Chandigarh, Maharashtra, Andhra Pradesh, East India, Jammu and Kashmir, Meghalaya, Arunachal Pradesh, West Bengal, Assam, South India, Sikkim, Manipur, Telangana, Mizoram, Haryana, Gujarat, Delhi, Madhya Pradesh, North India, Bihar, Kerala, Central India, Odisha, Jharkhand, West India, Chhattisgarh, Uttar Pradesh, All India

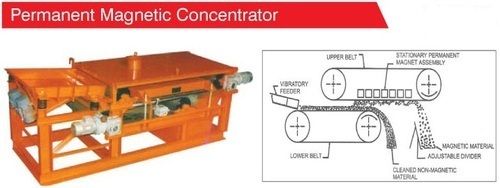

Product Description

We put forth our efforts as a renowned manufacturer and supplier to provide best quality of High Intensity Magnetic Roller System. This roller system is widely used for separating weakly particles of iron from various products. This roller system finds application in industries like food, mineral, glass and ceramic. This roller system is manufactured from high quality materials in compliance with quality standards of the industry. Offered High Intensity Magnetic Roller System is available at a reasonable price.

Features:

- Excellent strength

- Longer functional life

- Resistance to corrosion

- Require minimum maintenance

Advanced Ferrous Separation Technology

Utilizing high-intensity rare earth magnets, this roller system ensures meticulous extraction of even the finest ferrous particles. Its dustproof casing and vibration-free operation make it suitable for demanding environments and sensitive materials, promoting optimized process integrity and product purity.

Customizable Design for Diverse Needs

With adjustable roller numbers, conveyor speed, feed size, and a range of mounting and control options, this system adapts to varying industry requirements. Its composite stainless steel body and polished/matte finish add both resilience and aesthetic appeal, while size and capacity can be tailored to fit operation scale.

Safe and Efficient Operation

Engineered with user safety in mind, the control panel offers both digital and manual operating modes, complete with advanced safety features. Capable of withstanding temperatures up to 80C and robust enough for continuous use, it maintains efficiency without compromising operator safety or system reliability.

FAQs of High Intensity Magnetic Roller System:

Q: How does the High Intensity Magnetic Roller System separate ferrous contaminants from dry materials?

A: The system uses high-intensity rare earth magnets within cylindrical rollers to attract and extract ferrous particles from dry materials passing through the belt conveyor. Its advanced magnetic field ensures even fine contaminants are effectively removed, enhancing product purity.Q: What industries can benefit from installing this magnetic roller system?

A: Industries such as mining, ceramics, chemicals, food processing, and plastics manufacturing benefit significantly from this system, as it provides precise separation of ferrous materials, safeguarding sensitive equipment and improving product quality.Q: When should I choose single, double, or triple roller configurations?

A: Select single rollers for moderate throughput and straightforward separation, double rollers for improved magnetic coverage and enhanced capacity, and triple rollers for demanding operations requiring maximum ferrous removal and highest processing rates.Q: Where is this system typically installed, and what is its mounting type?

A: The system is designed for floor-mounted installation in industrial processing areas. Its compact, customized width and robust construction make it suitable for a wide variety of plant layouts and production environments.Q: What are the key safety and control features of the systems control panel?

A: The control panel includes both digital and manual operation modes, integrated safety features such as emergency stop and overload protection, ensuring safe, reliable, and adaptable control for operators.Q: How can the adjustable conveyor speed and feed particle size improve process flexibility?

A: Adjustable conveyor speed lets operators fine-tune the separation process for different material types and feed volumes, while accommodating particle sizes up to 5 mm ensures optimal magnetic interaction and collection efficiency.Q: What advantages do rare earth magnets, specifically NdFeB/N52, deliver in this system?

A: NdFeB/N52 rare earth magnets provide exceptionally strong magnetic fields, resulting in superior separation of even very fine ferrous particles and improving overall operation throughput and product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese